Biomass and Bioenergy Research Facilities and Equipment

Facilities: Bioprocessing Laboratory

Bioprocessing is the use of biological means or naturally occurring entities like microbes, plant and animal tissue, enzymes and other biochemical constituents to treat, convert, and produce various materials. Bioprocessing can be used to solve problems ranging from environmental remediation and wastewater treatment to medical and diagnostic applications, and beyond.

The Bioprocessing Laboratory at North Carolina A&T is committed to advancing the ideals of Biosystems Engineering, combining basic science of biology with engineering principles. In an effort to minimize waste and determine methods to recycle these materials, problem sources of interest are identified and environmentally sound solutions are then sought. This laboratory evaluates the application of using various types of organisms to produce beneficial products. The lab is involved in the research and development of methods that involve extraction, purification, and the qualitative and quantitative analysis of various compounds produced by means of fermentation.

The Bioprocessing Laboratory also plays a role in providing students with hands-on experience in research that complements their classroom studies. The lab environment is geared towards encouraging active learning and enhancing the student’s performance skills. In a broader context, students seeking a secondary degree are provided with research projects that will enable them to not only refine their analytical skills, but also obtain practical real world research experience.

The goal of this laboratory is to design methods that will help to preserve and make the best use of our natural resources. Ultimately, the research work performed in this lab will enable us to apply what has been learned to help solve various problems in the agriculture and food industries.

The Bioprocessing lab at Sockwell collaborates with various laboratories on N.C. A&T’s campus: the Analytical Services Laboratory and Food Safety Microbiology Laboratory are both located at Carver Hall.

Equipment

|

|

Anaerobic Digester: The Armfield anaerobic digester promotes the decomposition of organic waste to simple organics and biogas. |

|

|

Bioreactors (Spiral Sheet/ Fluidized Bed): These bioreactors encourage high rate bioreactions of substrated or immobilized microorganisms. |

|

|

Fermentors (NBS BioFlo III/ BioFlo 110): Provide optimal conditions for the conversion of complex compounds and the production of value-added by-products. |

|

|

Filtration systems (GE Osmonics and Consep/Optisep): High refining filtration for the concentration and recovery of low molecular weight proteins. |

|

|

Freeze dryer (Labconco - courtesy of Dr. Ibrahim, Food Science): 6L capacity freeze dryer for the preservation of biologicals via water removal. |

|

|

Gas Analyzer (GEM-500): Used in the analysis of various landfill gases produced. |

|

|

High Performance Liquid Chromatography (Waters): Analysis of eluted compounds in liquid matrices by means of RI and/or UV detection. |

|

|

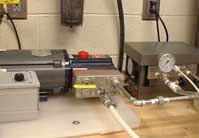

Parr Oxygen Bomb Calorimeter: Measures heat/energy reactions produced as a result of combustion of solid or liquid fuel, waste, and other combustible organic material. |